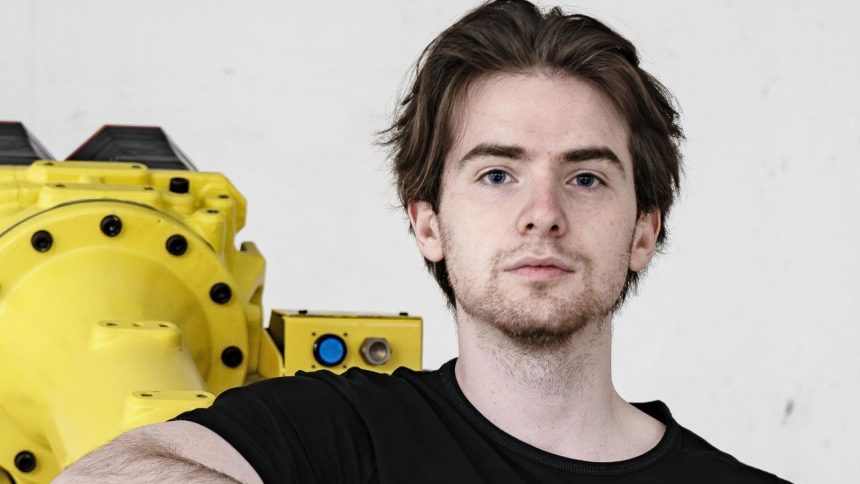

SAEKI, a Swiss robotics startup specializing in automated manufacturing, is disrupting traditional supply chains with its promise of faster, cheaper, and greener production. Founded in 2021 as a spin-out from ETH Zurich, SAEKI has developed a unique robotic system integrating 3D printing and machining capabilities, enabling the on-demand creation of complex components from high-grade, recyclable plastics. This innovative approach has attracted significant attention, culminating in a recent $6.7 million seed funding round, bringing the company’s total funding to $10 million. This injection of capital will fuel SAEKI’s ambitious expansion plans, including the establishment of new manufacturing facilities and further refinement of its technology.

SAEKI’s core innovation lies in its robotic platform, which combines additive manufacturing (3D printing) with machining capabilities. This allows the company to produce highly customized parts with intricate designs, catering to diverse industry needs. Unlike traditional manufacturing processes that rely on subtractive methods and often result in material waste, SAEKI’s additive approach utilizes only the necessary material, minimizing waste and enhancing cost-effectiveness. The layered construction inherent in 3D printing also facilitates precise tailoring of components to meet exact specifications, further boosting efficiency. The recyclable nature of the high-grade plastics used further underscores SAEKI’s commitment to sustainability, aligning with growing environmental concerns.

The construction industry has emerged as an early adopter of SAEKI’s technology. Traditionally, constructing concrete structures requires the creation of wooden molds, a process that is both time-consuming and wasteful. SAEKI’s robots can rapidly print these molds from recyclable plastic, dramatically reducing production time and eliminating the need for single-use wooden forms. The molds can be easily recycled after use, further contributing to a circular economy model within the construction sector. Beyond construction, SAEKI has also made inroads into the automotive and aerospace sectors, producing composite components for clients including a UK-based supercar manufacturer. The company’s technology caters to a range of industrial businesses requiring customized components for their plant and machinery, demonstrating the versatility of its robotic platform.

SAEKI’s commitment to streamlining production extends beyond its innovative manufacturing process. The company has launched an online platform that simplifies the ordering process for customers. Potential clients can upload their designs, receive instant quotes, and approve production with a click. This seamless integration with SAEKI’s automated robotic system eliminates human intervention, accelerating production timelines and increasing efficiency. From design submission to finished product, the entire process is optimized for speed and transparency. This digital interface reflects SAEKI’s forward-thinking approach to manufacturing, leveraging technology to enhance customer experience and further differentiate itself from traditional manufacturers.

Despite the clear advantages of SAEKI’s technology, the company acknowledges the challenge of gaining customer trust in a relatively new manufacturing paradigm. The speed and cost-effectiveness of SAEKI’s production process can sometimes seem too good to be true for potential clients accustomed to traditional methods. Therefore, clearly communicating the benefits and intricacies of its robotic manufacturing process is crucial for SAEKI’s continued success. Building confidence in its innovative technology is essential for wider adoption and market penetration. Demonstrating the reliability and consistency of its robotic production will be key to overcoming skepticism and fostering long-term customer relationships.

SAEKI’s business model is built on three pillars: speed, cost-efficiency, and sustainability. The automated nature of its robotic system, coupled with the direct-to-robot ordering platform, minimizes production time. The elimination of material waste and the precise application of materials through 3D printing contribute to lower production costs. The use of recyclable plastics and the option for customers to return used molds for recycling highlight SAEKI’s commitment to environmentally responsible manufacturing. These combined advantages position SAEKI as a compelling alternative to traditional manufacturing methods, particularly in a market grappling with labor shortages and increasing demands for sustainable practices.

Looking ahead, SAEKI aims to expand its global reach by establishing additional manufacturing facilities. The company also plans to enhance its robotic platform by incorporating automated milling capabilities, further improving the precision and complexity of the components it can produce. SAEKI’s vision extends beyond simply manufacturing parts; the company seeks to transform the manufacturing landscape by offering a more efficient, sustainable, and technologically advanced approach to production. With its innovative technology and ambitious expansion plans, SAEKI is poised to become a significant player in the future of industrial manufacturing.