Richard Mille, the avant-garde watchmaker renowned for its groundbreaking designs and cutting-edge materials, has consistently pushed the boundaries of horology. A key element of this pursuit has been a long-standing collaboration with North Thin Ply Technology (NTPT), a Swiss company specializing in advanced composite materials. This partnership has yielded a series of innovative watch cases that are as visually striking as they are technically impressive. From the robust Carbon TPT to the vibrant Quartz TPT, these materials not only provide exceptional strength and lightness but also contribute to the distinctive aesthetic that defines Richard Mille timepieces. The RM 65-01, a split-seconds chronograph drawing inspiration from the fast-paced world of motorsports, exemplifies this approach. Recently updated with vibrant hues like banana yellow, baby blue, and soft gray, the RM 65-01 showcases a new material that mimics the feel of plastic yet boasts several times the strength of stainless steel, appealing to a younger generation of watch enthusiasts.

The symbiotic relationship between Richard Mille and NTPT has become so integral to the watchmaker’s identity that a dedicated facility was established within NTPT’s Lausanne headquarters in 2018. This pristine, white-walled space houses the specialized machinery required for the meticulous creation of Richard Mille watch cases. Within this controlled environment, a large robotic printer methodically lays down thin strips of a viscous material onto a spotless surface. Clad in white coveralls, technicians oversee the automated process. In the background, spools of translucent fibers are fed into equipment that transforms them into ultra-thin layers of unidirectional tape (UD), the very material the robotic printer is meticulously depositing. This highly controlled process ensures the precision and consistency required for the demanding specifications of Richard Mille watches.

The genesis of these colorful and textured composites, however, wasn’t a deliberate aesthetic pursuit but rather a response to a technical challenge posed by Richard Mille himself. Over a decade ago, NTPT was already supplying Richard Mille with Carbon TPT cases, but the brand’s eponymous founder sought to introduce brighter hues to his designs. This seemingly simple request sparked a period of intense experimentation at NTPT. The initial attempts to create a pure white composite unexpectedly yielded a vibrant red, marking the beginning of a journey into the world of colored composites. This serendipitous discovery ultimately led to the development of the vibrantly colored Quartz TPT materials seen in contemporary Richard Mille watches.

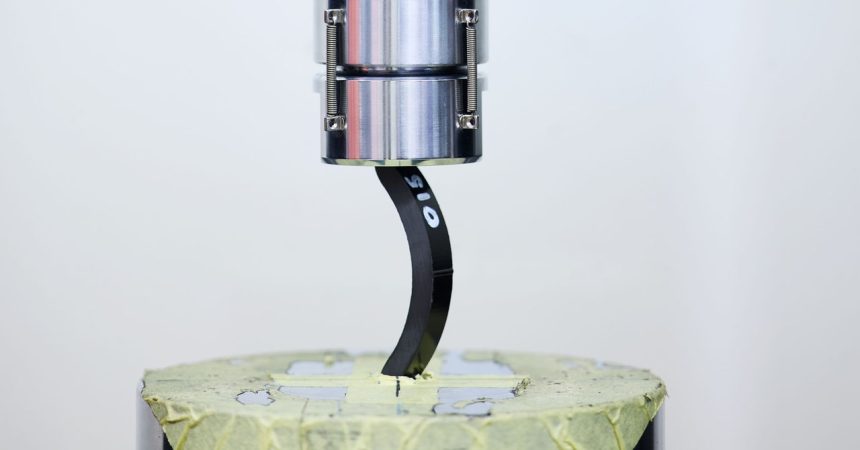

The underlying principle behind these advanced composites, whether Kevlar, fiberglass, forged carbon, or even the Quartz TPT, mirrors that of more commonplace materials like concrete or MDF. Tiny strands of a specific material are embedded within a binding matrix, typically a polymer resin such as epoxy. This mixture is then carefully shaped, subjected to intense pressure, and finally cured with heat. The resulting composite material is remarkably light yet incredibly strong, with the embedded fibers acting as reinforcing elements within the surrounding matrix. This combination of lightness and strength is crucial for watchmaking, where durability and comfort are paramount.

The process of creating these specialized composites, however, is far more complex than that of simpler materials. For Carbon TPT and Quartz TPT, hundreds of layers of the unidirectional tape are meticulously stacked, with each layer oriented at a precise angle relative to the others. This specific alignment is crucial for maximizing the material’s strength and stiffness in multiple directions. The stacked layers are then impregnated with a resin and subjected to high pressure and temperature in an autoclave, a specialized oven used for composite curing. This process consolidates the layers and cures the resin, resulting in a solid block of material. This block is then carefully machined to the exacting specifications of the watch case, revealing the unique, layered pattern characteristic of Richard Mille’s TPT materials. The complexity of this process underscores the technical prowess of both Richard Mille and NTPT.

The collaboration between Richard Mille and NTPT has not only revolutionized watch case materials but has also pushed the boundaries of material science. The pursuit of a white composite led to a spectrum of vibrant colors and innovative textures, ultimately enhancing the aesthetic and technical capabilities of Richard Mille’s timepieces. This ongoing partnership exemplifies the brand’s commitment to innovation and its relentless pursuit of pushing the boundaries of haute horlogerie. The result is a collection of timepieces that are as visually captivating as they are technically impressive, solidifying Richard Mille’s position at the forefront of contemporary watchmaking.