When tackling the challenges of obtaining a full-resolution 3D model, many 3D modelers and.Handleders have expressed the difficulty and time-consuming nature of 3D scanning. The excitement among creators shows that they’ve come to rely on third-party scanners like Makerboard 3D and Testament 3D, believing these tools can simplify the process. However, the author acknowledges the limitations of 3D scanners: while they are invaluable tools for 3D modelers, they do not provide a perfect final product on their own. This leads to further questions about the best use of 3D scanners, whether 3D rendering is sufficient for artistic purposes or if post-processing and electrolysis are needed. The makerboard series, highlighted by Henri Robbins, takes a step forward with a simple, intuitive, and affordable solution. This futuristic, self-contained 3D scanner promises to revolutionize the art of creating detailed, high-quality 3D models.

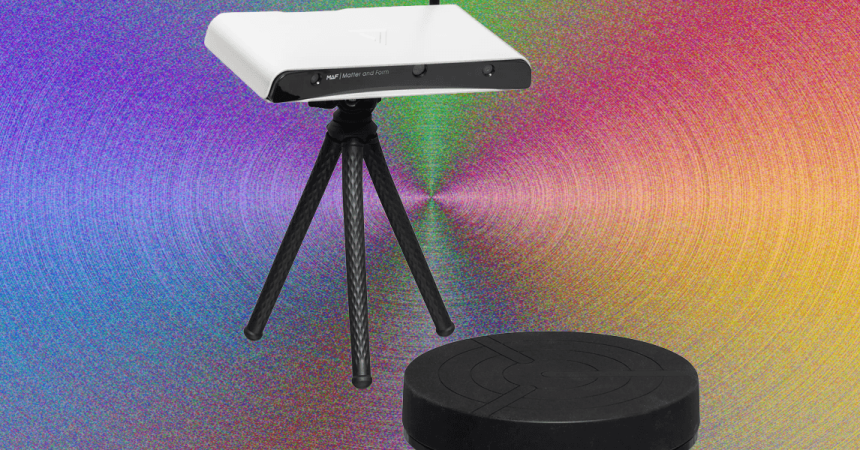

The makerboard 3D, announced as the first small, affordable, and effective 3D scanner with an aim to make high-resolution modeling accessible, combines strengths from both hardware and software. Built on a small laptop and equipped with onboard processing and calibration tools, it is ideal for those who prefer portability to cumbersome desktop equipment. High tangibility with a motorized turntable allows for precise alignment, delivering results in minutes once set up. The company claims that 3D scanning often results in high-quality models that can be printed, suggesting a potential reduction in the need for expensive post-processing. However, the author emphasizes that even with the best tools, perfection remains elusive. While some 3D scanners require extensive calibration and setup, the makerboard goes beyond these metrics, offering a seamless and user-friendly experience.

Setting up the makerboard 3D is straightforward, requiring a simple and attackable interface to begin scanning. Henri Robbins provides a series of tutorials across multiple platforms—wireless connection via an included antenna, terrestrial Ethernet access using a connecting rod, or direct 4×4 device partnerships. Starting the process is intuitive, with a start page and a seamless browser-based interface for access. The virtual reality shooter on the makerboard serves as a visual confirmation of successful trauma, streamlining the setup. Henri’s campaigns alongside software vendors are highlighted, underscoring the makerboard’s potential for rapidbuiltin scalability.

Troubleshooting the makerboard 3D is相对来说 more approachable. Issues are often resolved through careful selection and adjustment of settings, thanks to a comprehensive and detailed interface. The 3D rendering consistently delivers high-quality results, allowing for the printing of katon Connectivity. The makerboard’s micro-movability and speed uncertain, but the author ultimately conveys that while thousands of models are producing, workflows inherently demand collaboration and resources. Shifting focus to future possibilities, the makerboard 3D suggests that adding RGB lighting could enhance realism without centralizing costs. The makerboard marks an important step in democratizing 3D scanning, making advanced tools accessible to a broader audience.

In conclusion, while 3D modeling remains a challenge for many, the makerboard 3D with its simplicity and ease of use offers a promising pathway toward a more accessible alternative to expensive 3D scanners. This technological breakthrough departs from the endless road of what can be done with 3D cameras, presenting an alternative reality where high-quality results are achievable with minimal effort. As industries look to modernize workflows, new tools and techniques could expand the scope of achievable results, further paving the way for futuristic advancements in creative technology.